In the competitive world of plastic manufacturing, productivity and precision are key factors that can determine the success of a production line. As manufacturers aim to reduce cycle times while maintaining high-quality output, innovations in tooling systems become essential. One such advancement is the 4 Station Tooling setup a highly efficient configuration that optimizes the thermoforming process through a multi-stage approach. In this article, we’ll explore what 4 Station Tooling is, how it works, its benefits, and why it has become a preferred solution for high-speed, high-volume thermoforming operations.

What is 4 Station Tooling?

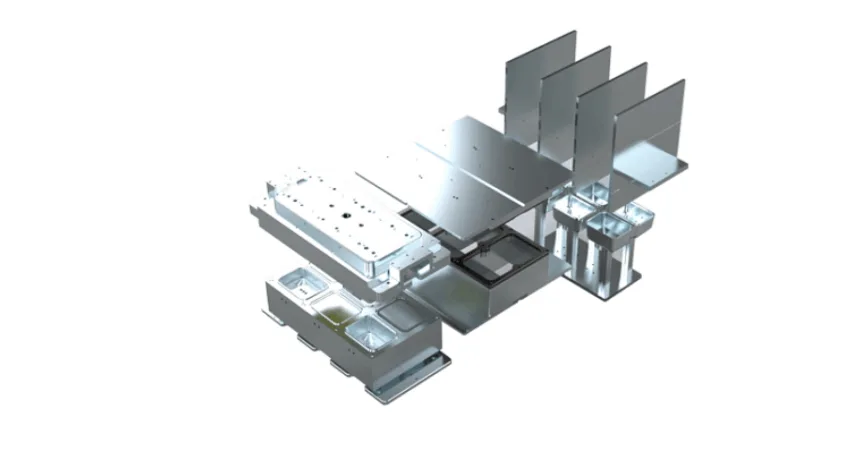

4 Station Tooling refers to a comprehensive tooling configuration used in thermoforming machines that operate across four distinct production phases:

Heating

Forming

Cooling

Trimming (or Cutting)

Each station within the system is equipped with purpose-built tooling designed to perform a specific role. Unlike traditional one- or three-station setups, 4 Station Tooling allows for greater control over each step of the process. This ensures that the plastic material is treated optimally at every stage from heating through final product cutting. This configuration is commonly used in fully automated thermoforming lines, especially in high-demand sectors like packaging, automotive, and medical devices.

How 4 Station Tooling Works

1. Heating Station

In the first station, a plastic sheet is heated to its forming temperature using infrared or contact heaters. The heating tooling ensures even heat distribution to prepare the material for precise forming.

2. Forming Station

Once heated, the sheet moves to the forming station. Here, 4 Station Tooling includes male or female molds, plug assists, and vacuum or pressure forming systems that shape the material into the desired form with high accuracy.

3. Cooling Station

After forming, the product enters a dedicated cooling station. This unique feature of 4 Station Tooling allows the part to cool down independently, preventing deformation and reducing cycle times. Tooling here includes chilled molds or airflow systems designed to stabilize the product’s structure quickly.

4. Trimming Station

The final stage involves trimming the formed part from the excess plastic. This is typically done with steel rule dies, punch tools, or CNC cutters. The tooling at this station ensures clean edges and precise dimensions.

Benefits of 4 Station Tooling

1. Improved Production Efficiency

By separating the forming and cooling stages, 4 Station Tooling allows each phase to operate optimally. This leads to shorter cycle times and higher throughput.

2. Enhanced Product Quality

Each process—heating, forming, cooling, and trimming—is handled by specialized tooling, resulting in better material handling, reduced warping, and improved surface finish.

3. Flexibility in Material and Product Design

The system is compatible with a wide variety of thermoplastics including PET, PP, PS, PVC, and ABS. This makes it suitable for a broad range of product designs and industrial needs.

4. Scalability for High-Volume Production

Thanks to its modular and automated design, 4 Station Tooling is ideal for mass production, with the capability to maintain consistent output over long runs.

5. Lower Downtime and Maintenance

By isolating each stage, the system allows for easier troubleshooting and maintenance. Tooling for individual stations can often be replaced or adjusted without halting the entire line.

Applications of 4 Station Tooling

4 Station Tooling is widely used in industries where precision, speed, and cleanliness are essential:

– Food Packaging

Used to create trays, cups, containers, and blister packs that meet strict hygiene standards.

– Automotive

Helps produce structural components like trunk liners, interior panels, and HVAC covers with uniform wall thickness and tight tolerances.

– Medical Devices

Used for forming clean, sterile packaging for syringes, surgical kits, and diagnostic devices.

– Consumer Electronics

Enables efficient production of cases, panels, and protective enclosures with exact specifications.

Design Considerations for 4 Station Tooling

When developing or investing in 4 Station Tooling, engineers and manufacturers must consider:

Draft angles for easy release from molds

Material shrinkage and its impact on final dimensions

Tool cooling systems for consistent part quality

Tooling material durability (commonly aluminum or steel)

Automated loading/unloading integration

Properly designed tooling ensures consistent performance and longevity in demanding production environments.

4 Station Tooling represents a significant step forward in the evolution of thermoforming technology. By breaking the process into four carefully controlled stages, manufacturers gain greater precision, faster production speeds, and more reliable output. Whether you’re working in food packaging, automotive, medical, or consumer products, adopting a 4 station system can dramatically improve both efficiency and product quality. As market demands continue to evolve, investing in advanced tooling solutions like 4 Station Tooling is not just a competitive advantage it’s a necessity.